The key role of CCS Hot Pressing Film in the composite molding process

In the rapidly evolving field of advanced materials and high-performance manufacturing, composite molding has become a cornerstone technology across industries such as aerospace, automotive, electronics, and renewable energy. At the heart of this sophisticated process lies a critical yet often overlooked component: the CCS (Carrier Composite Surface) Hot Pressing Film. This specialized functional film plays a pivotal role in ensuring the quality, consistency, and performance of composite materials during the molding phase. As one of China’s leading innovators in functional film materials, Anhui Yanhe New Materials Co., Ltd. has been at the forefront of developing and manufacturing high-performance CCS Hot Pressing Films that meet the rigorous demands of modern industrial applications.

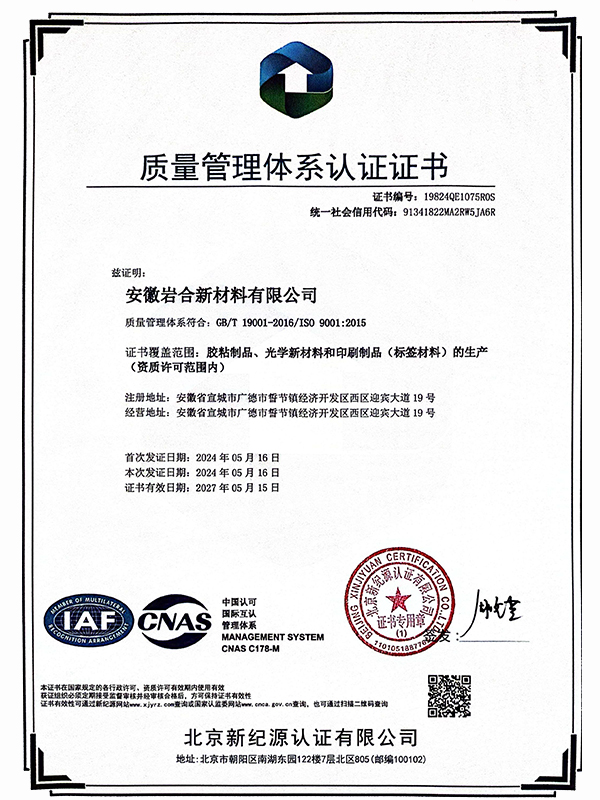

Established in 2012 and strategically located within the Guangde Economic Development Zone West on a 17-acre site, Anhui Yanhe New Materials Co., Ltd. has built a strong reputation for its expertise in specialty labeling materials, functional adhesive tapes for the electronics industry, and advanced functional film solutions. The company’s core strength lies in its ability to tailor material properties through precise surface coating technologies, enabling customized solutions that align with the specific functional requirements of its clients. By leveraging cutting-edge new material research and development techniques, Yanhe New Materials has positioned itself as a trusted partner for global manufacturers seeking reliable, high-performance materials for complex production processes.

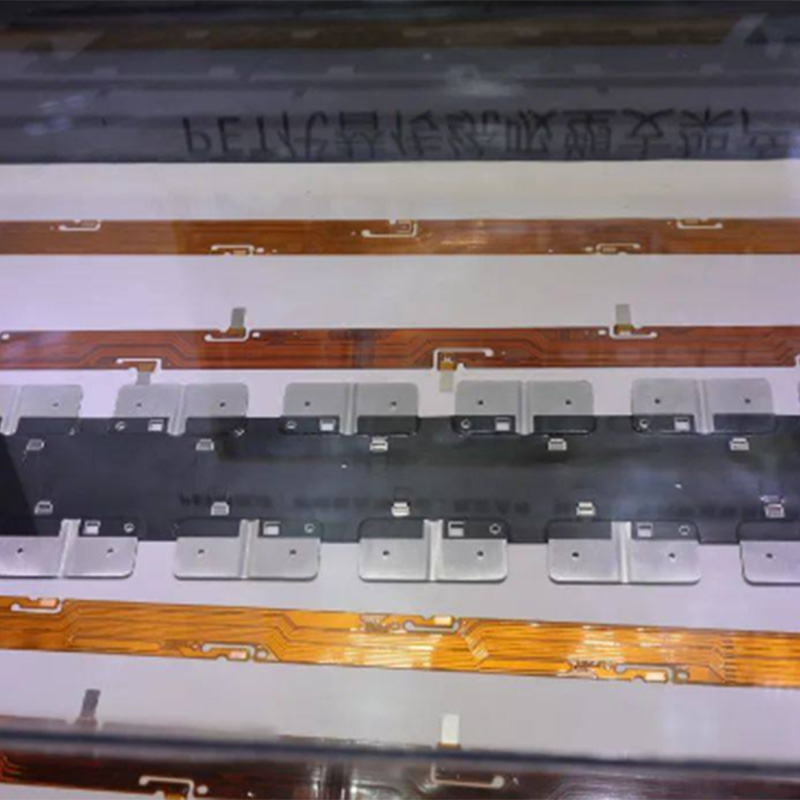

The CCS Hot Pressing Film is a critical enabler in composite molding, where layers of fiber-reinforced materials (such as carbon fiber or fiberglass) are bonded together under heat and pressure to form lightweight, high-strength components. During this process, the CCS film acts as a release layer and surface modifier between the composite part and the mold or caul plate. Its primary functions include preventing adhesion to the mold, ensuring uniform heat transfer, minimizing surface defects, and preserving the aesthetic and structural integrity of the final product. Without a high-quality CCS film, manufacturers risk surface imperfections, delamination, and inconsistent curing—issues that can lead to costly rework or product failure.

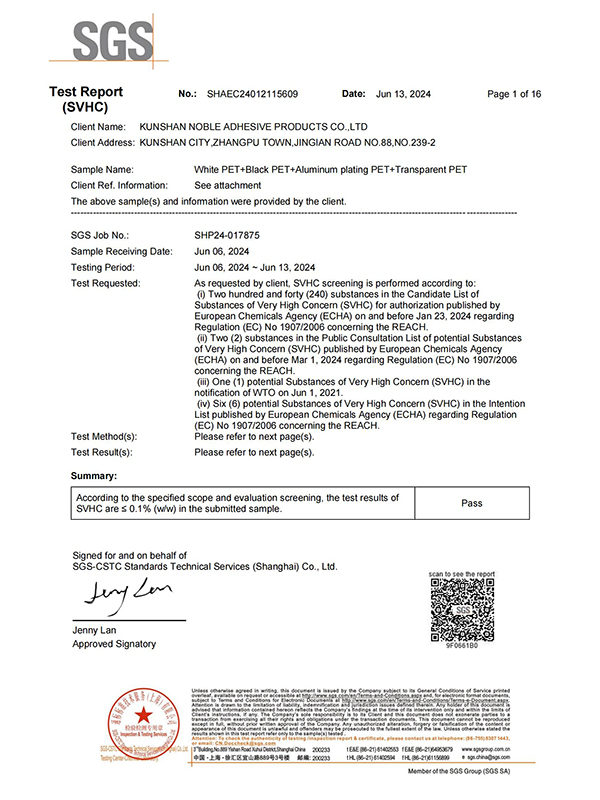

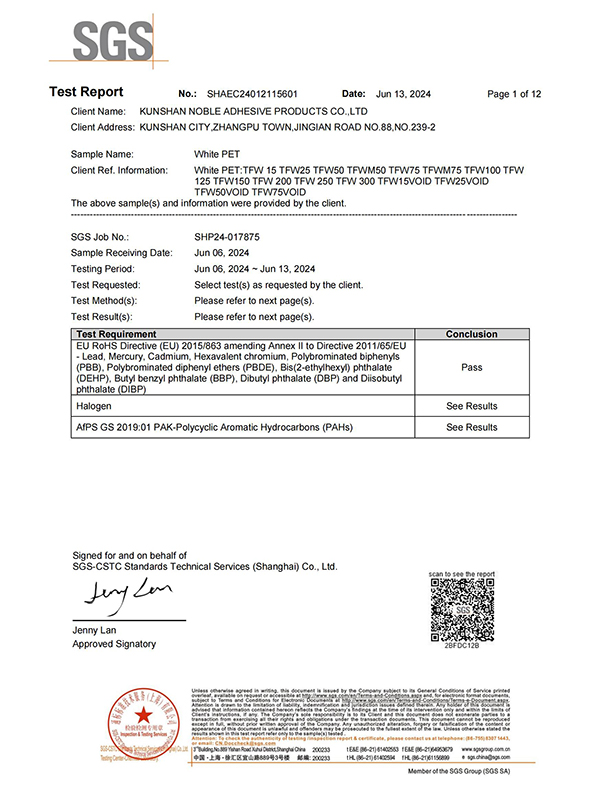

Anhui Yanhe New Materials has developed a proprietary line of CCS Hot Pressing Films that excel in thermal stability, chemical resistance, and mechanical durability. These films are engineered with multi-layer composite structures and precision-applied surface coatings that optimize release performance while maintaining dimensional stability under high temperatures (typically ranging from 120°C to 180°C). The company’s R&D team works closely with material scientists and engineers to fine-tune surface energy, coefficient of friction, and tensile strength, ensuring compatibility with a wide range of resin systems, including epoxy, phenolic, and BMI (bismaleimide).

One of the key advantages of Yanhe’s CCS films is their adaptability. Drawing from its extensive experience in functional adhesive and film technologies, the company offers customized formulations that can be modified for specific molding cycles, pressure conditions, and end-use environments. For example, in the aerospace industry, where surface finish and material purity are paramount, Yanhe provides ultra-clean CCS films with low particulate emission and high release reliability. In contrast, for high-volume automotive production, the company delivers cost-effective, reusable films that maintain performance over multiple press cycles.

Furthermore, Anhui Yanhe New Materials’ collaborative approach extends beyond product development. The company actively partners with universities and scientific research institutions both domestically and internationally to stay at the cutting edge of material science innovation. These collaborations have led to breakthroughs in nanocoating technologies and smart surface engineering, which are now being integrated into the next generation of CCS films. Such advancements not only enhance performance but also contribute to more sustainable manufacturing practices by reducing waste and energy consumption during the molding process.

In conclusion, the CCS Hot Pressing Film is far more than a passive component in composite molding—it is a critical enabler of quality, efficiency, and innovation. As industries continue to demand lighter, stronger, and more complex composite structures, the importance of high-performance auxiliary materials like CCS films will only grow. With its strong foundation in R&D, customized manufacturing capabilities, and customer-centric innovation, Anhui Yanhe New Materials Co., Ltd. is well-positioned to lead the way in providing integrated functional material solutions that empower the future of advanced manufacturing. Through continued investment in technology and collaboration, the company remains committed to delivering excellence—one functional film at a time.

English

English русский

русский Español

Español عربى

عربى