Is Anhui Yanhe New Materials Co., Ltd.'s aluminum foil fiberglass felt resistant to chemicals or corrosive substances?

In the realm of industrial materials, the demand for products that can withstand harsh environments is ever - increasing. One such material that has been garnering significant attention is aluminum foil fiberglass felt. Anhui Yanhe New Materials Co., Ltd., founded in 2012 and situated on a 17 - acre site in Guangde Economic Development Zone West, has emerged as a prominent player in manufacturing this innovative product.

The Composition of Aluminum Foil Fiberglass Felt

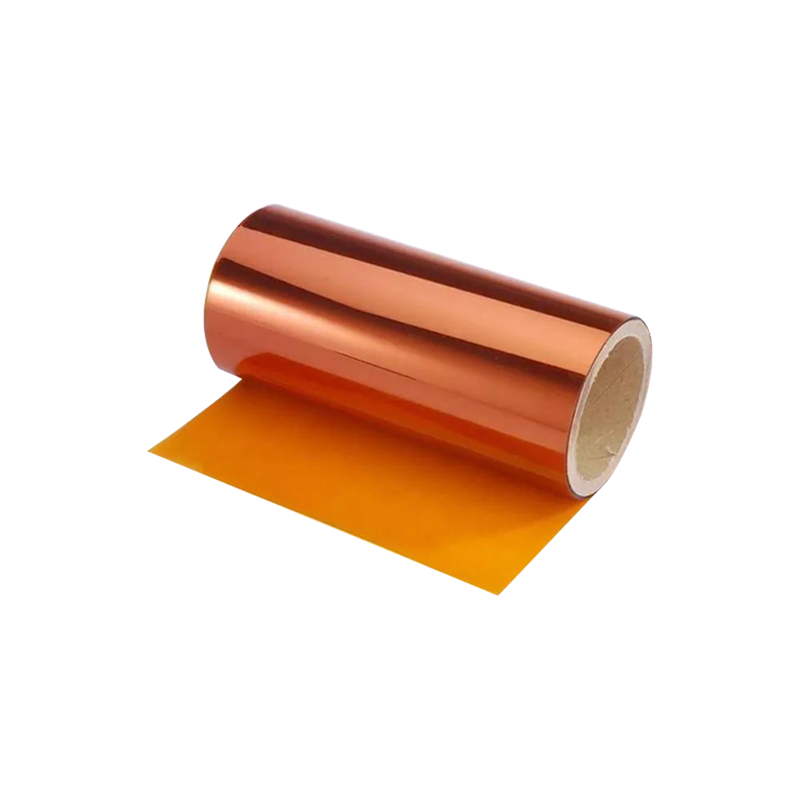

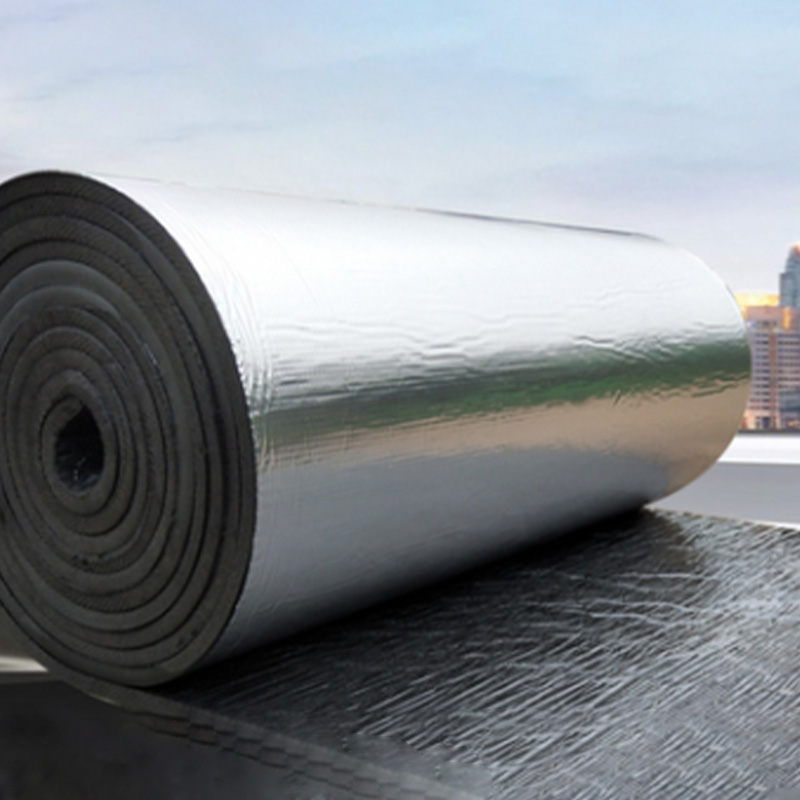

Aluminum foil fiberglass felt is a composite material. The core is fiberglass felt, which is renowned for its thermal insulation and sound - dampening properties. Overlaid on this is a layer of aluminum foil. The fiberglass provides a robust structure, while the aluminum foil imparts additional functionality.

Chemical Resistance and Corrosion Resistance Mechanisms

Aluminum Foil's Role in Chemical Resistance

Aluminum, in its pure form, has a natural oxide layer that forms upon exposure to air. This thin oxide layer acts as a protective barrier against many common chemicals. When it comes to Anhui Yanhe's aluminum foil fiberglass felt, the aluminum foil on the surface significantly enhances its chemical resistance. The aluminum foil can resist the penetration of a wide range of acidic and alkaline substances. For instance, weak acids like acetic acid, which are present in some industrial cleaning agents, find it difficult to corrode the aluminum foil due to this protective oxide layer. In fact, aluminum's chemical stability is well - documented, and this characteristic is harnessed in the manufacturing of the aluminum foil for the fiberglass felt.

Fiberglass Felt's Contribution to Corrosion Resistance

The fiberglass felt component of the material also plays a crucial role in corrosion resistance. Fiberglass is inherently resistant to most common corrosive agents. It is non - reactive with water, which is a common source of corrosion in many industrial settings. Whether it is in a high - humidity environment or in contact with moisture - laden air, the fiberglass felt does not degrade or corrode. Additionally, fiberglass is not affected by biological agents such as mold and mildew, which are often corrosive to other organic - based materials. This makes the aluminum foil fiberglass felt suitable for use in environments where biological corrosion could be a concern, like in some food processing plants or in areas with high humidity.

Applications Demonstrating Resistance

Automotive Industry

In the automotive sector, Anhui Yanhe's aluminum foil fiberglass felt is used in various applications. For example, it is placed in the engine compartments. Engine compartments are not only hot but also have a complex chemical environment. There are oil mists, coolant leaks, and exhaust fumes. The aluminum foil fiberglass felt installed here needs to withstand these substances. The aluminum foil resists the acidic nature of exhaust fumes, while the fiberglass felt remains stable in the presence of oil and coolant. This application showcases the material's ability to resist chemicals and corrosive substances in a real - world, demanding environment.

Industrial Equipment

In industrial settings, the material is used for insulating pipes and machinery. Industrial environments can be extremely harsh, with the presence of strong chemicals used in manufacturing processes. Pipes carrying chemicals like sulfuric acid or sodium hydroxide are often insulated with aluminum foil fiberglass felt. The material's resistance to these highly corrosive substances ensures that the insulation remains intact and effective over time. Machinery operating in chemical plants, where there are airborne chemical particles, also benefits from the use of this material. The aluminum foil fiberglass felt protects the machinery from corrosion caused by these particles, thereby extending the lifespan of the equipment.

Anhui Yanhe's Manufacturing Excellence

Anhui Yanhe New Materials Co., Ltd. has state - of - the - art manufacturing facilities. The company's production process is designed to optimize the chemical and corrosion resistance of the aluminum foil fiberglass felt. The company's R & D team, which collaborates with universities and scientific research institutions at home and abroad, is constantly working on improving the material's performance. By applying advanced surface coatings based on the functional requirements of different surfaces, Anhui Yanhe ensures that the aluminum foil fiberglass felt can meet the most stringent technical requirements. This dedication to research and development, combined with top - notch manufacturing capabilities, results in a product that offers excellent resistance to chemicals and corrosive substances.

In conclusion, Anhui Yanhe New Materials Co., Ltd.'s aluminum foil fiberglass felt is highly resistant to chemicals and corrosive substances. The combination of the chemical properties of the aluminum foil and the inherent corrosion - resistant nature of the fiberglass felt, along with the company's manufacturing prowess, makes it a reliable choice for applications in diverse industries where resistance to harsh chemical environments is a prerequisite.

English

English русский

русский Español

Español عربى

عربى