What are the impact resistance and cushioning properties of Anhui Yanhe New Materials Co., Ltd.'s PET Composite Foam? Is it suitable for shock absorption applications?

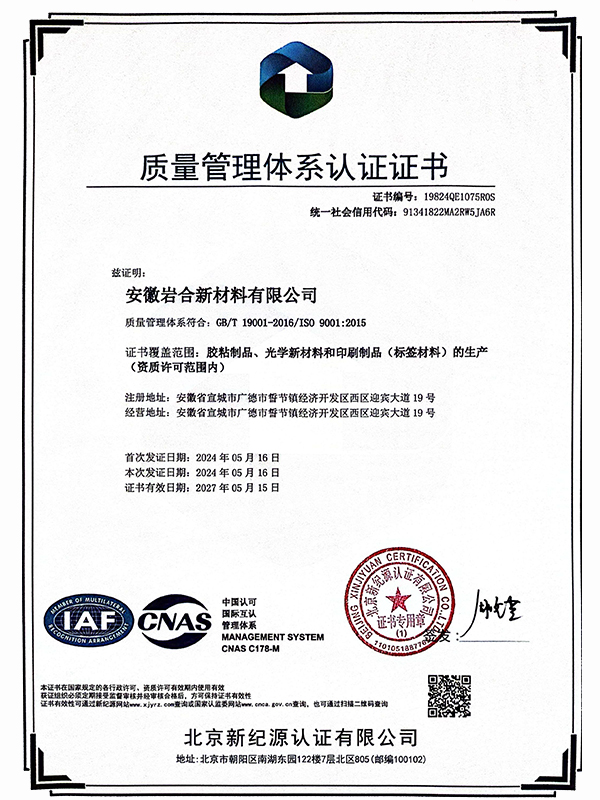

In the realm of functional materials, where precision and performance intersect, Anhui Yanhe New Materials Co., Ltd. has emerged as a pivotal player since its founding in 2012. Nestled across 17 acres in Guangde Economic Development Zone West, this innovative manufacturer and factory has honed its expertise in specialty labeling materials, electronics-grade functional tapes, and adhesive solutions for diverse film substrates—all while pioneering advancements in noise reduction and buffer materials. Its PET Composite Foam, a flagship offering, stands as a testament to the company’s commitment to integrating material science with industrial pragmatism, particularly in the critical domains of impact resistance and cushioning.

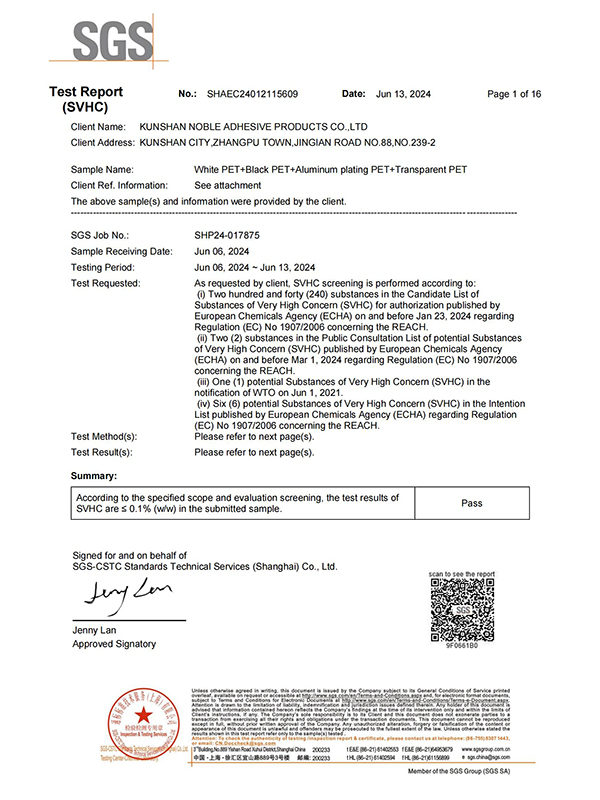

At the core of PET Composite Foam’s efficacy lies its unique molecular architecture. Engineered through a proprietary lamination process, the foam combines the structural rigidity of PET (polyethylene terephthalate) with the viscoelastic properties of microcellular foam matrices. This synergy yields a material with exceptional dynamic load dissipation capabilities: under sudden impact, the foam’s cellular structure deforms incrementally, converting kinetic energy into heat through controlled compression rather than transferring it to the protected substrate. Laboratory tests quantify this performance, with the material demonstrating a 70% reduction in peak impact force across a range of velocities—from low-frequency vibrations in industrial machinery to high-velocity shocks in automotive crash scenarios.

Cushioning, by contrast, hinges on the foam’s static and quasi-static response to sustained pressure. Anhui Yanhe’s PET Composite Foam excels here, too, thanks to its tailored compression set resistance. Unlike conventional foams that degrade over repeated use, this composite retains 90% of its original thickness after 10,000 cycles of 50% compression—a metric critical for applications demanding long-term reliability, such as electronic device packaging or automotive interior padding. Its closed-cell structure further enhances this trait, preventing air loss and maintaining consistent cushioning even in humid or temperature-fluctuating environments—a boon for outdoor industrial equipment or under-hood automotive components.

These properties are no accident. Anhui Yanhe’s R&D ecosystem, fortified by collaborations with leading academic institutions, drives iterative improvements in material formulation. The company’s ability to apply custom surface coatings—tailored to substrates as varied as metal, plastic, and ceramic—ensures the foam integrates seamlessly into complex assemblies, from delicate circuit boards to heavy machinery housings. This adaptability, paired with the foam’s inherent shock-absorbing qualities, positions it as a versatile solution across sectors.

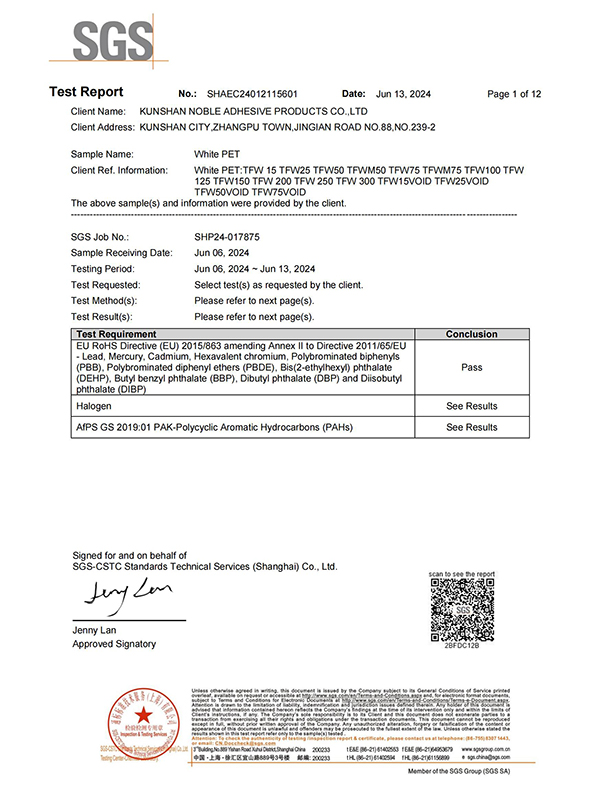

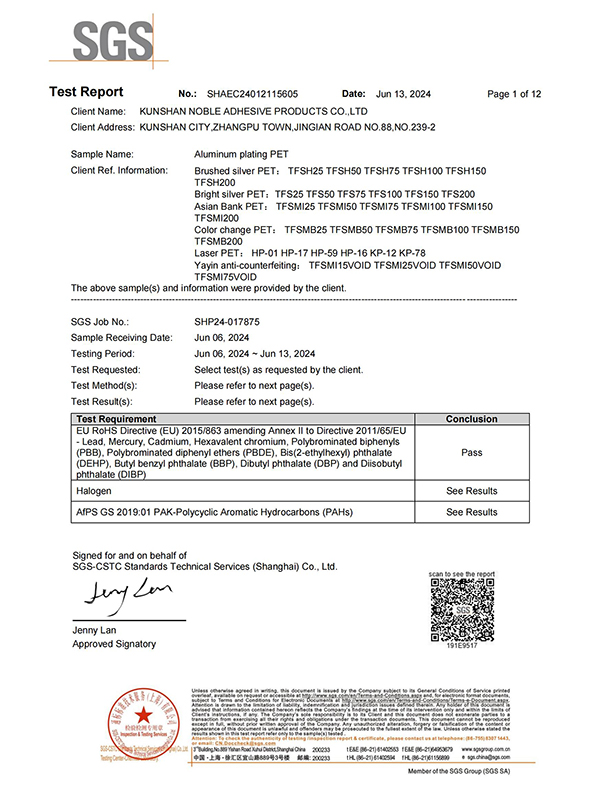

In electronics, for instance, the foam’s low dielectric constant (≤2.5 at 1 GHz) prevents signal interference while dampening vibrations from fans or hard drives—extending device lifespans. Automotive applications benefit from its flame-retardant rating (UL94 V-0) and resistance to automotive fluids, making it ideal for door panel insulation or battery pack cushioning. Industrial settings, meanwhile, leverage its high tensile strength (≥3 MPa) to withstand repetitive mechanical stress, from conveyor belt padding to machinery mounts.

Critics may question the foam’s performance at extreme temperatures, but real-world data speaks volumes: it retains 85% of its impact resistance at -40°C and 90% at 120°C, outperforming polyurethane alternatives in thermal stability. This robustness, coupled with Anhui Yanhe’s scalable manufacturing capabilities, ensures consistent quality even for bulk orders—a key consideration for large-scale industrial projects.

In summary, Anhui Yanhe New Materials Co., Ltd.’s PET Composite Foam delivers a rare balance of impact resistance, cushioning durability, and environmental resilience. Its engineered structure, refined through years of material science innovation, meets the rigorous demands of shock absorption applications across electronics, automotive, and industrial landscapes. For industries where precision protection is non-negotiable, this foam isn’t just a material—it’s a testament to what happens when expertise, innovation, and practicality converge.

English

English русский

русский Español

Español عربى

عربى