Choosing the Right Label Material: How Paper, Film, and Specialty Materials Impact Durability and Performance

When it comes to labeling, selecting the right label material is crucial to ensuring that your products are not only identifiable but also stand the test of time. Different applications require different materials, and the choice between paper, film, and specialty materials can significantly affect the performance, durability, and overall look of your labels. Whether you're labeling products for industrial, commercial, or personal use, understanding the unique characteristics of each type of label material will help you make a more informed decision that aligns with both your functional and aesthetic needs.

Paper labels are among the most commonly used materials, primarily due to their cost-effectiveness and versatility. They are ideal for products that don't face extreme conditions, making them perfect for indoor applications or items that will be sold quickly. Paper labels, available in a variety of finishes and textures, can be easily printed with high-quality graphics, making them suitable for branding and marketing. However, while paper labels are great for basic use, they may not hold up well when exposed to moisture, extreme temperatures, or rough handling. For longer-lasting durability, it’s important to consider more resilient materials like synthetic films.

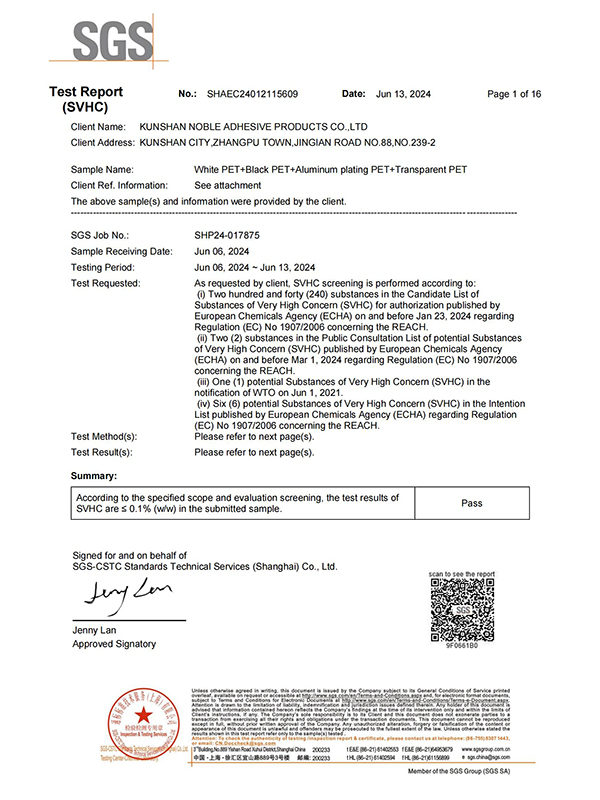

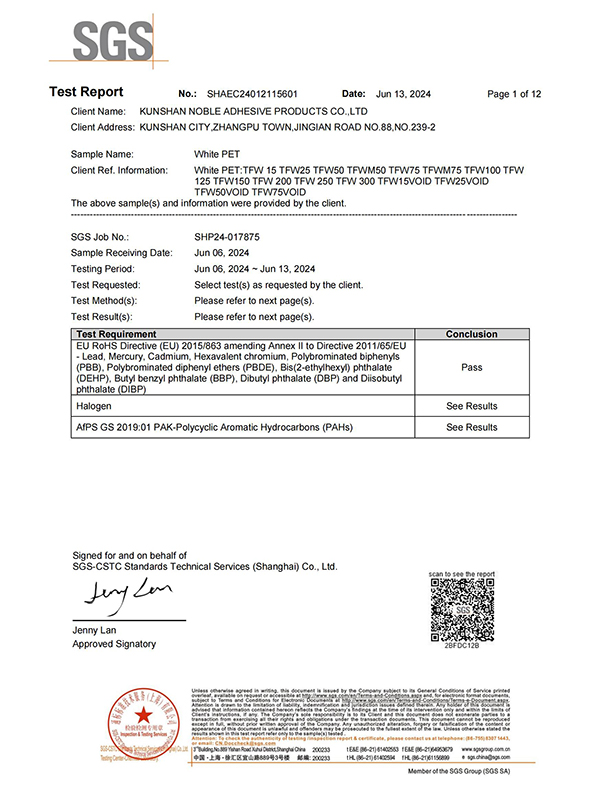

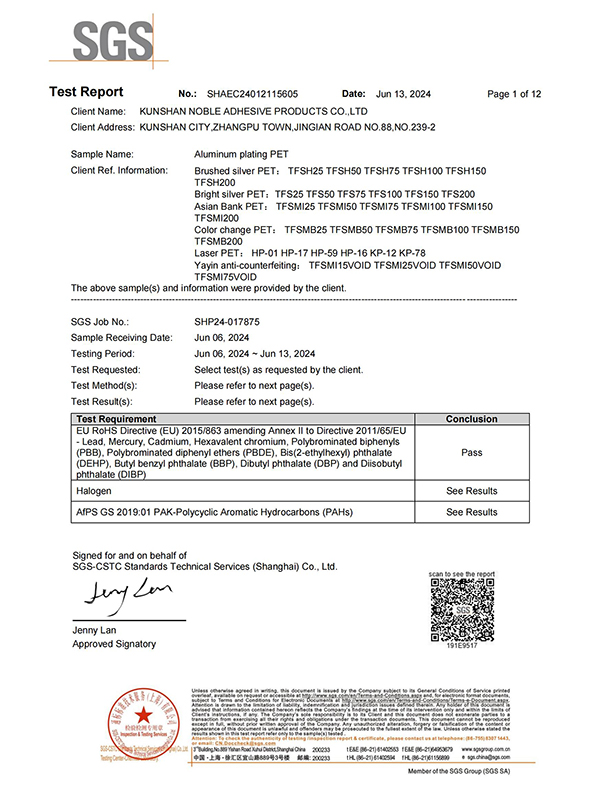

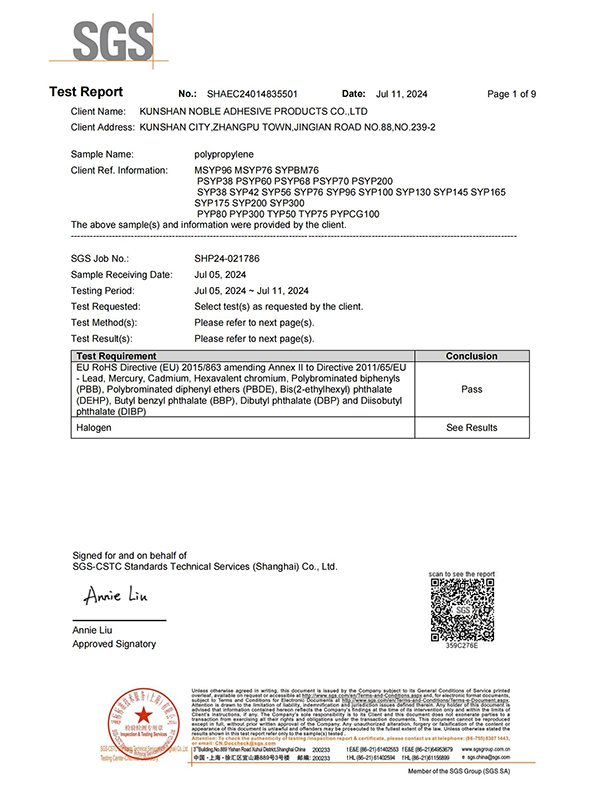

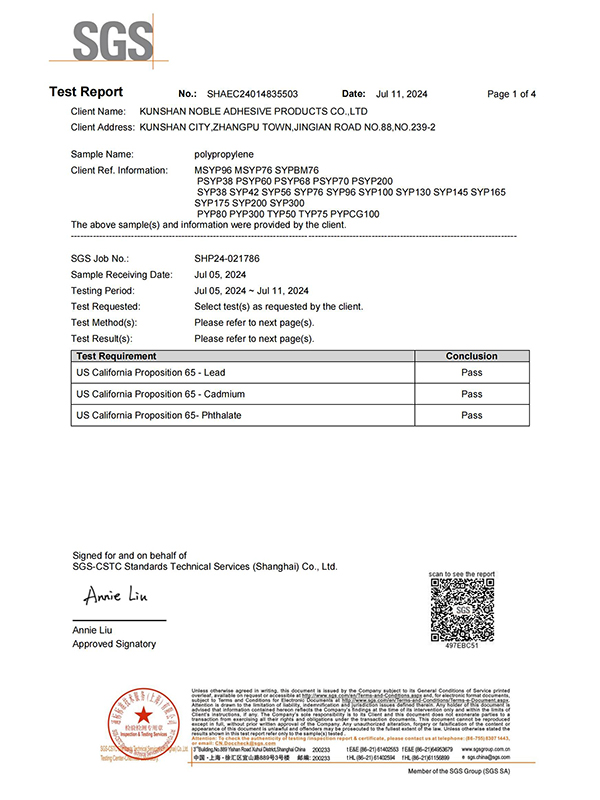

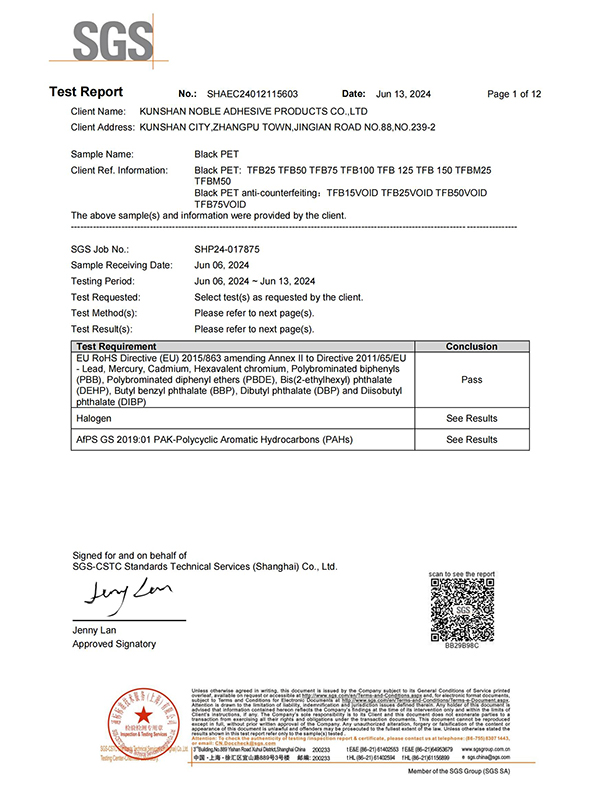

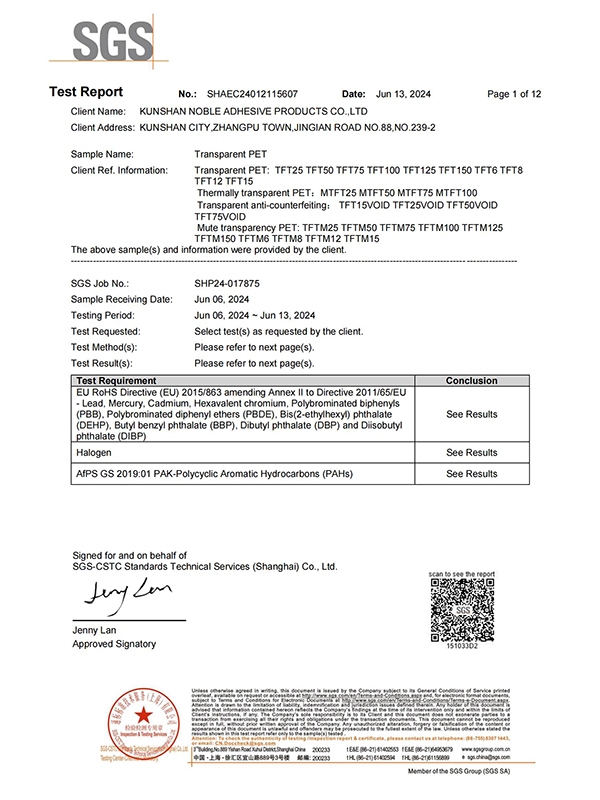

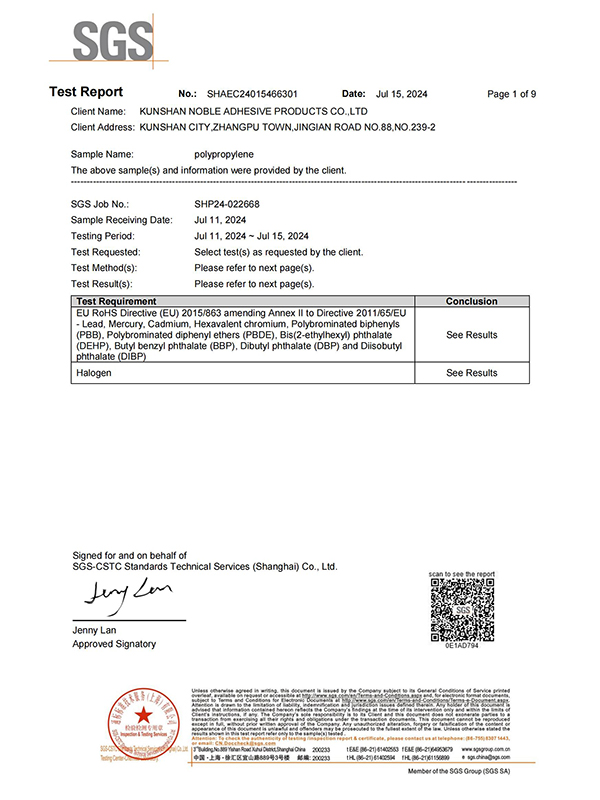

Film labels, such as those made from polyester (PET), polypropylene (PP), or vinyl, offer exceptional durability, making them the go-to choice for products that need to withstand harsh conditions. These materials are known for their resistance to water, UV rays, and tearing, which is why they are often used for labeling outdoor equipment, chemicals, and high-end products. Film labels can maintain their integrity and appearance even in extreme environments, ensuring your branding and information stay intact longer than paper alternatives. With film labels, you also have the advantage of customization, as they can be engineered to meet specific requirements, such as chemical resistance or enhanced adhesion.

For applications that require both durability and flexibility, specialty label materials like cotton, fabric, or metalized options offer additional benefits. These materials are ideal for products that need to maintain a premium appearance while also providing exceptional resistance to wear and tear. Fabric labels, for instance, are commonly used in the garment industry, offering a soft yet durable option for clothing labels. Metalized labels are perfect for products in luxury markets, combining an attractive sheen with durability. Choosing a specialty label material for these applications ensures that your products stand out while maintaining top-tier quality.

When deciding on the right label material, it's essential to consider the specific requirements of your application, such as exposure to moisture, temperature extremes, and handling. For instance, products that will be stored in freezers or exposed to high heat require materials with temperature resistance, while labels for outdoor use need materials that can withstand UV degradation. By selecting the right material, you’re not just protecting your brand’s image but also ensuring that your labels function as intended in real-world conditions.

The printability of a label material also plays a crucial role in its overall performance. Some materials, such as glossy films, provide a smooth surface that enhances print quality, ensuring vibrant, sharp graphics and text. Meanwhile, matte finishes may be preferred for a more subdued, professional appearance. Different printing techniques, such as flexographic or digital printing, can be applied to various materials, but it’s important to ensure compatibility between your chosen label material and the printing method to achieve the best possible results.

Additionally, environmental concerns are shaping the future of label materials. As more companies strive for sustainability, there is a growing demand for eco-friendly label materials that minimize environmental impact. Recyclable films, biodegradable adhesives, and FSC-certified paper options are gaining traction in industries that prioritize eco-conscious practices. By selecting a sustainable label material, you can not only meet regulatory requirements but also appeal to environmentally aware consumers who value brands that are committed to reducing their carbon footprint.

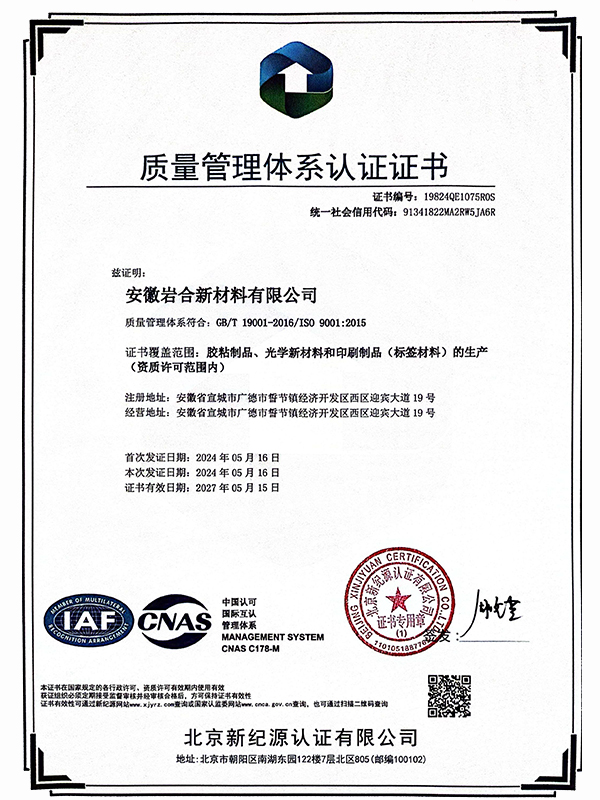

At Huiyuan, we understand that each labeling requirement is unique, and we offer a wide range of label materials to meet the diverse needs of our customers. Our self-adhesive materials are designed to provide the perfect balance of durability, printability, and adhesion, making them suitable for a variety of applications. Whether you're looking for paper labels for a short-term project or high-performance films for products that require long-lasting durability, we have the right solution to meet your specifications. By choosing the right label material, you can ensure that your products remain well-marked, identifiable, and attractive throughout their life cycle.

In conclusion, the choice of label material directly impacts both the functionality and appearance of your product’s labeling. Understanding the pros and cons of paper, film, and specialty materials allows you to make a more informed decision based on your specific needs. With the right label material, you can achieve not only superior performance but also a better customer experience that reflects the quality of your products. By partnering with a trusted supplier like Huiyuan, you gain access to high-quality materials and expert guidance to ensure your labeling solutions are up to the task

English

English русский

русский Español

Español عربى

عربى