Substrate: Synthetic paper

Glue thickness: Customizable

180 ° steel plate peeling force: Customizable

Coming From China, Marketing To The World.

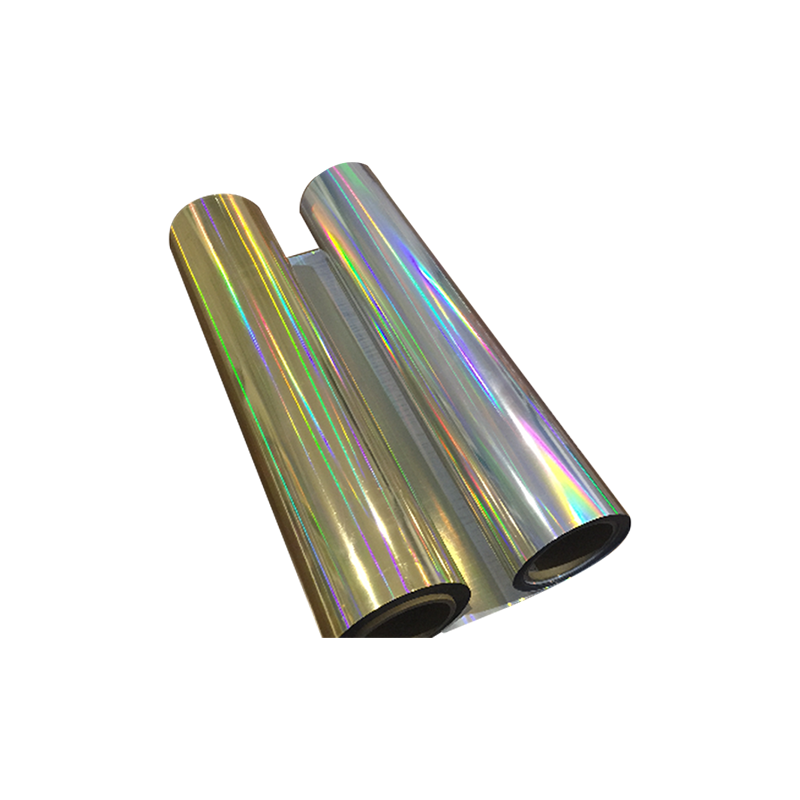

HPSYL 38#(60G)-JS Grid Pattern Pearlescent Film Synthetic Paper

-

Product Description

HPSYL 38#(60G)-JS Grid Pattern Pearlescent Film Synthetic Paper is an innovative material designed for premium packaging and printing applications. It combines the durability of synthetic paper with the unique lustrous shine of pearlescent film, offering exceptional visual appeal and tactile experience. The surface features an intricate grid pattern with a strong sheen, adding a touch of luxury and artistry to any package or printed product.

This synthetic paper boasts water resistance, oil resistance, and tear resistance, making it capable of withstanding various environmental challenges. It is ideal for use in demanding scenarios such as fashion product packaging, cosmetics packaging, or premium gift packaging. HPSYL 38#(60G)-JS Grid Pattern Pearlescent Film Synthetic Paper enhances the distinctive charm of products and boosts brand value and market competitiveness.

With processing performance, HPSYL 38#(60G)-JS Grid Pattern Pearlescent Film Synthetic Paper can be easily printed, embossed, and cut. Its flexibility allows it to be applied widely across various packaging designs, and it is compatible with a wide range of printing equipment, helping businesses reduce costs and improve efficiency during production.

Substrate

Synthetic paper

Glue thickness

Customizable

180 ° steel plate peeling force

Customizable

-

Inquiry

Yanhe

Was Established in 2012

Founded in 2012, As China HPSYL 38#(60G)-JS Grid Pattern Pearlescent Film Synthetic Paper suppliers and HPSYL 38#(60G)-JS Grid Pattern Pearlescent Film Synthetic Paper company, Anhui Yanhe New Material Co., Ltd. is located on a 17-acre site in Guangde Economic Development Zone West. The Company mainly develops and manufactures specialty labeling materials, functional tapes for the electronics industry. adhesive products for various functional film materials, and is able to fully meet the technical requirements of its customers' products by applying corresponding surface coatings based on the functional requirements of the customers' different surfaces. With the industry's advanced new material research and development technologies, customized manufacturing capabilities, and the ability to collaborate with universities and scientific research institutions at home and abroad, we are committed to providing customers with integrated solutions for functional materials.

Company Video

OEM / ODM SERVICE

We provide professional OEM and ODM service to meet your needs

-

Laptop Battery Noise Reduction Label Stickers: Materials, Function, Compliance & Specification Guide

What Are Laptop Battery Noise Reduction Label Stickers? Laptop battery noise reduction label stickers are specialized adhesive labels applied directly to the surface of laptop batt...

READ MORE -

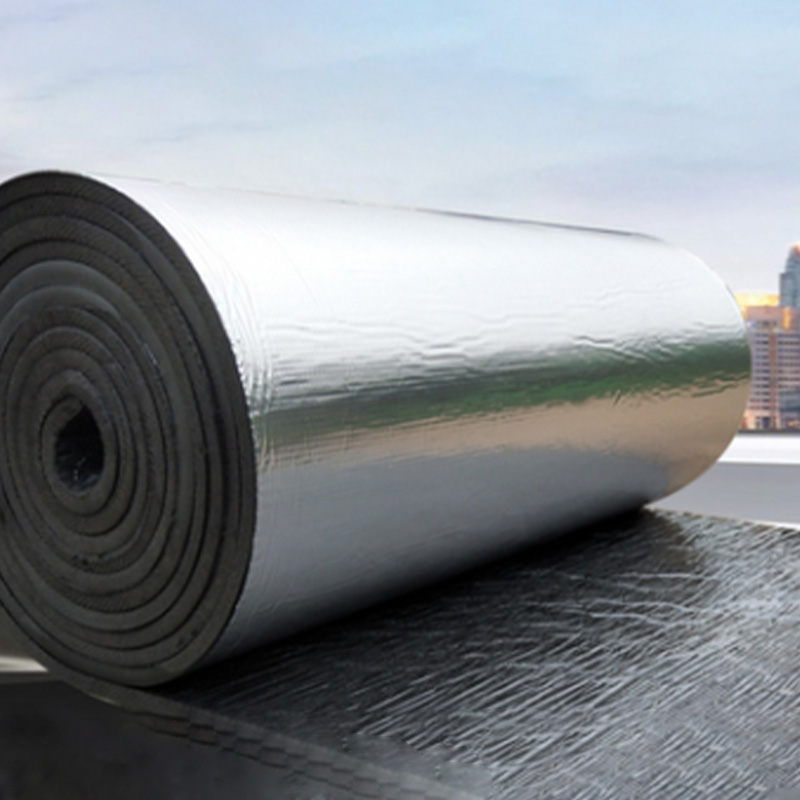

Composite Structure of Aluminum Foil Fiberglass Felt Aluminum foil fiberglass felt is a composite insulation material formed by laminating aluminum foil onto fiberglass felt throug...

READ MORE -

Introduction to Pearlescent Film Synthetic Paper Pearlescent film synthetic paper is a high-performance material that combines the durability of synthetic paper with a lustrous pea...

READ MORE -

Introduction to Washable Laser Film Washable laser film is a specialized printing medium designed to transfer high-resolution images onto fabrics and textiles using laser printers....

READ MORE

English

English русский

русский Español

Español عربى

عربى